Cement and Concrete are often confused with one another. It is important to differentiate these two materials though because they both have unique qualities. Cement is a greyish powder that acts as the glue that holds concrete components together. Without cement, we would not have concrete. The main type of cement used today is known as “Portland Cement” and is made by burning limestone and clay. This material is also chemically combined with calcium, aluminum, silicon, and iron during its manufacturing process.

Step One: Requiring Raw Materials

Limestone and clay can be found in shallow water areas between 3o degrees north latitude and 30 degrees south latitude. The material is then crushed into smaller sizes, about 3 inches big, so it can later be combined with other strengthening materials.

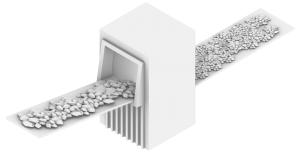

Step Two: Crushing and Combining

Once the raw limestone and clay are brought to the manufacturing factory, they are crushed into small 3-inch pieces if not done so already. The crushed rock is then combined with other ingredients such as iron ore, fly ash, and other materials depending on the required chemical proportions. The mixed components are then fed into a cement furnace.

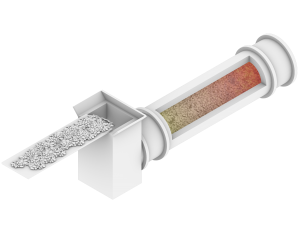

Step Three: Heating

The furnace used in this step can be compared to a brick oven, except that this is a rotary furnace. Within the rotary furnace, the materials are heated to about 2700 degrees fahrenheit to ensure that the cement components combine with one another. The product of this process is called “Clinkers”. These clinkers are grey balls that are about the size of a marble.

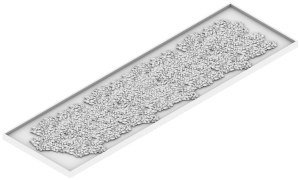

Step Four: Finalizing the Material

Once the clinkers are cooled, machines grind them with a small amount of gypsum and limestone. The additional limestone helps strengthen the final material, while the gypsum slows the cement’s reaction time with water. This step is important because when water is added to cement, it only has a few hours before it fully hardens. It is important to ensure that there is an adequate amount of time to cast the concrete with the cement before it fully hardens. After this final mixing and grinding step, the material is shipped out to be used on site.

Work Cited:

– https://theconstructor.org/building/manufacture-of-cement/13709/

– https://www.thermofisher.com/blog/mining/the-cement-manufacturing-process/

– https://www.youtube.com/watch?v=NM_F1t-aG9s