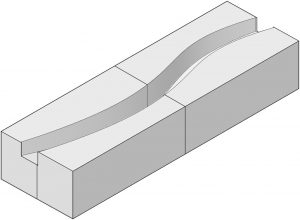

In order to properly manufacture the project’s terrocatta pieces, a cast must be drawn of the desired form. Above is the ideal form that we would aim to cast. The cast, as seen, will be split into four pieces in order to avoid creases on the finished piece.

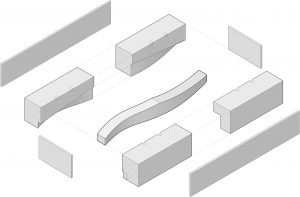

Above is an exploded axon of how the casting case would opperate. The four pieces will cast around the desired clay form, and then be further braced by plywood boards on each face of the casting.

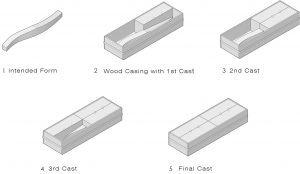

Above is a step by step process of how the clay would be cast using our casting system. Once the disired form is identified the casts will be placed one at a time in order to avoid creases and air bubbles. The casts also have small divits on their top faces to allow the user to easily lift the cast vertically when the clay is dried and ready to be removed.

Above are the general dimensions of the built wall, as well as a singular module.

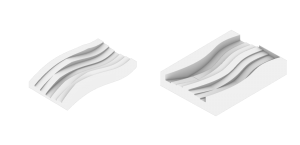

This above photo is an exploration of how multiple modules could be cast at the same time.