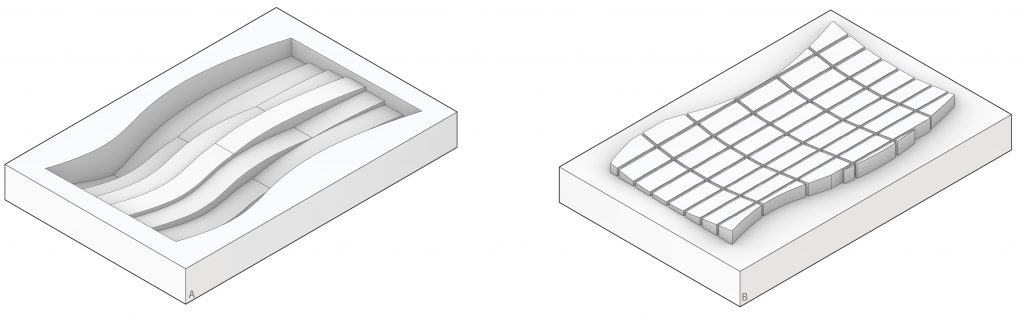

A ram press process for the fabrication of our prototype would be most efficient. Press molds would be formed to accommodate the fabrication of the façade terra cotta design as well as a mold creating the webbing for the interior.

The clay would be packed into the ‘A’ mold, while mold ‘B’ would be pressed into the clay to create the webbing. The mold would be hydraulically pressed to create the desired form. The ‘B’ mold also accommodates for the curve that is generated in the terra cotta. The air forces water in the plaster die to the surface, releasing the clay from the bottom of the mold.