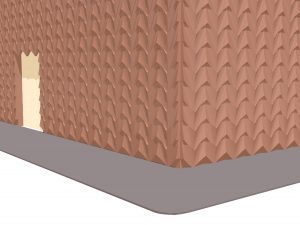

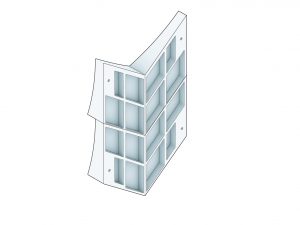

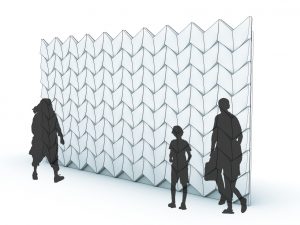

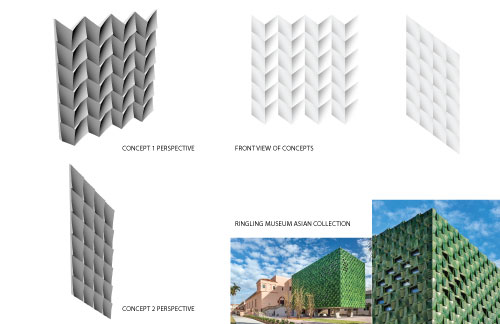

One of the major discussion points during our review was the title choice. We chose Sequence for the way the tiles fit together when all pointing same direction. This was taken as being a specific construction strategy which didn’t apply to our current design. Another topic that was brought up was how our design meets the ground. Currently, it might be easy for someone or something to break off the bottom row due to the closeness to the ground and the shape. Adding an alternate shape could make an interesting ground condition and might create more of a finished look where the tiles end.

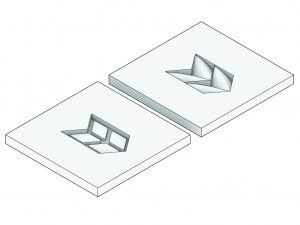

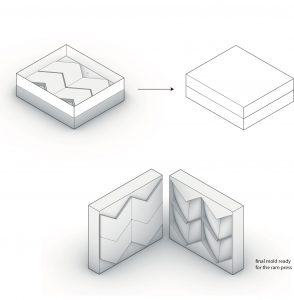

Updated ram press mold.

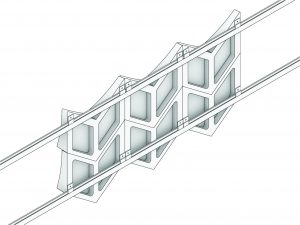

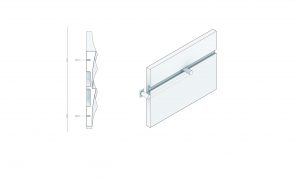

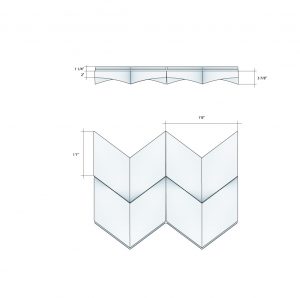

The Monarch clip is used to attach each piece to a track. The back webbing was also modified and is now 1 1/8″ with bigger spaces between.

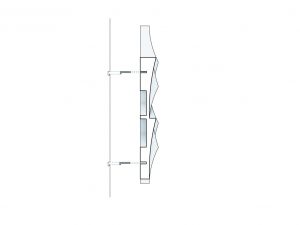

Section showing the connection to the track.

These three renders show how light would create different shadows at different times of the day. These specific examples are 6am, 12pm, and 6pm.

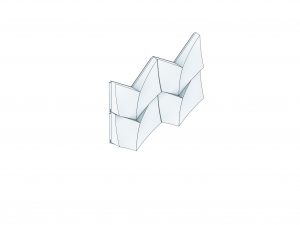

We modified the back of the tile into a simpler lip that could sit on a track. This makes the overall piece easier to ram press because there are no longer any undercuts.

This section shows how each piece would sit on a track system behind.

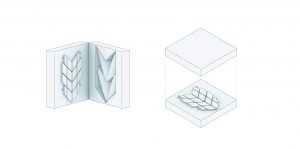

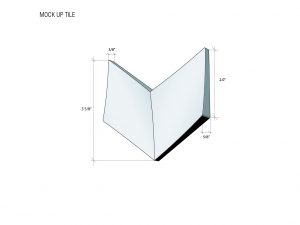

This is how we would create the mold for our tile to be used in the ram press.

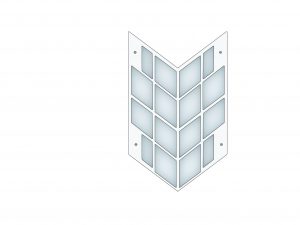

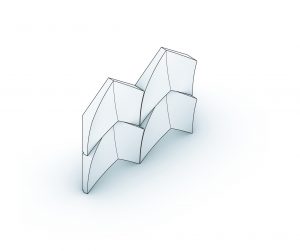

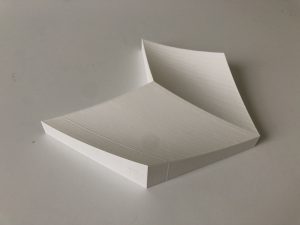

The tile was edited to get rid of any right angles. All of the edges are now rounded and the sides were angled inward 2 degrees.

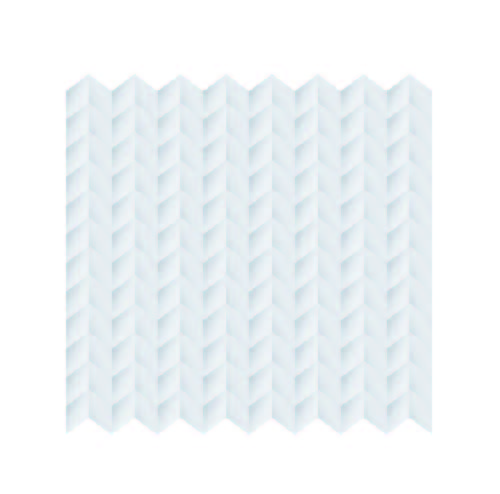

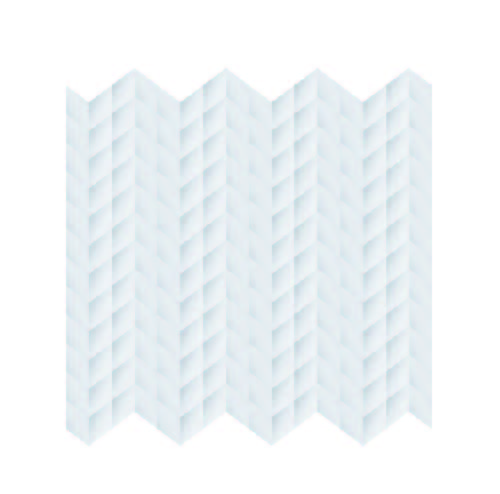

This is a close up view of how the newly angled tiles would fall together. This iteration is done with only single pieces which shows off more of the rounded edges and little openings they create.

Single 3D printed tile at full scale.

Combined tile 3D printed at full scale.

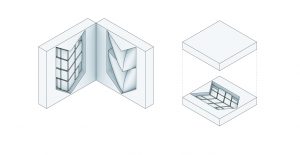

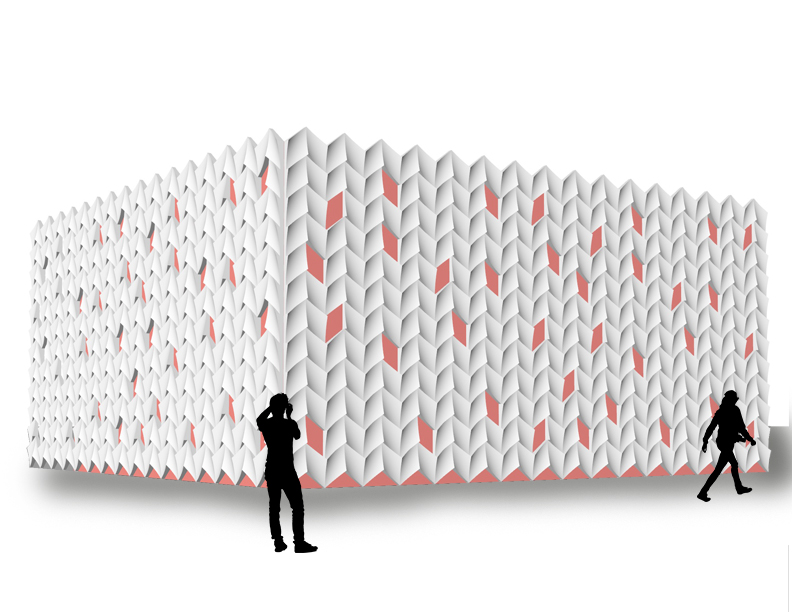

Rendered view of full scale installation. We experimented with removing certain tiles to create different patterns. This also will affect how the light moves over the surface. Depending on what type of material is behind the terracotta tiles, whether it be glass or something else transparent, light can be brought into the interior.

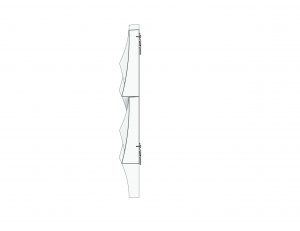

Elevation view 1

Elevation view 2