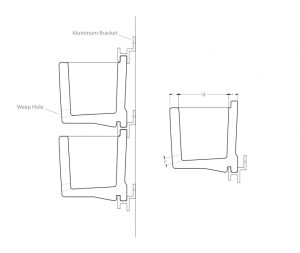

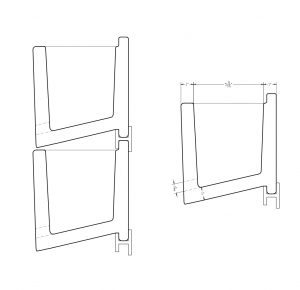

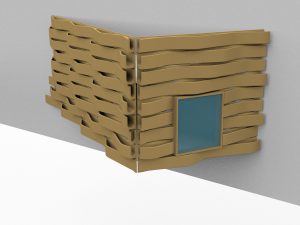

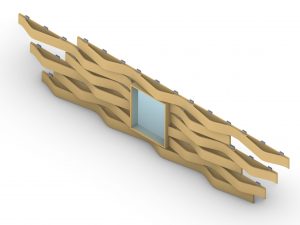

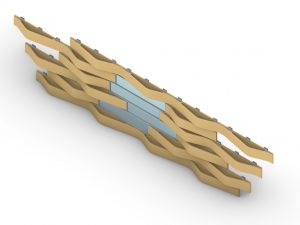

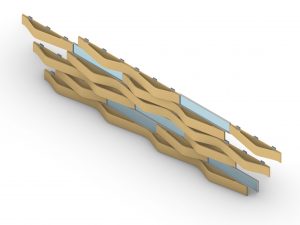

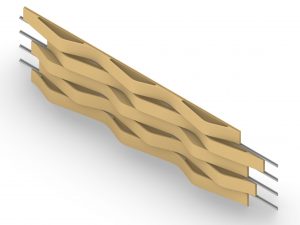

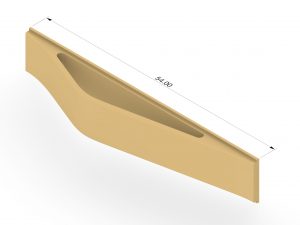

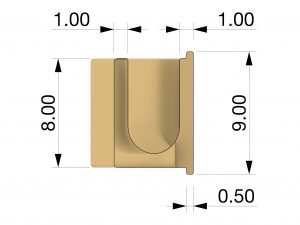

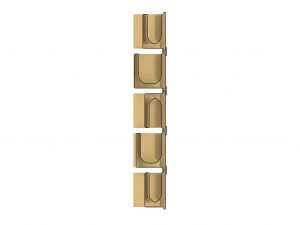

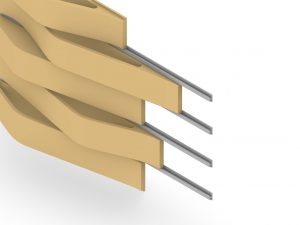

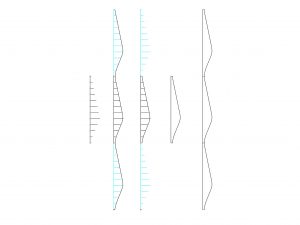

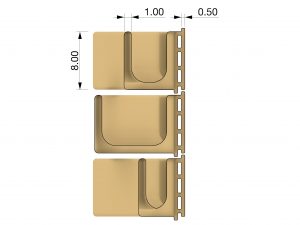

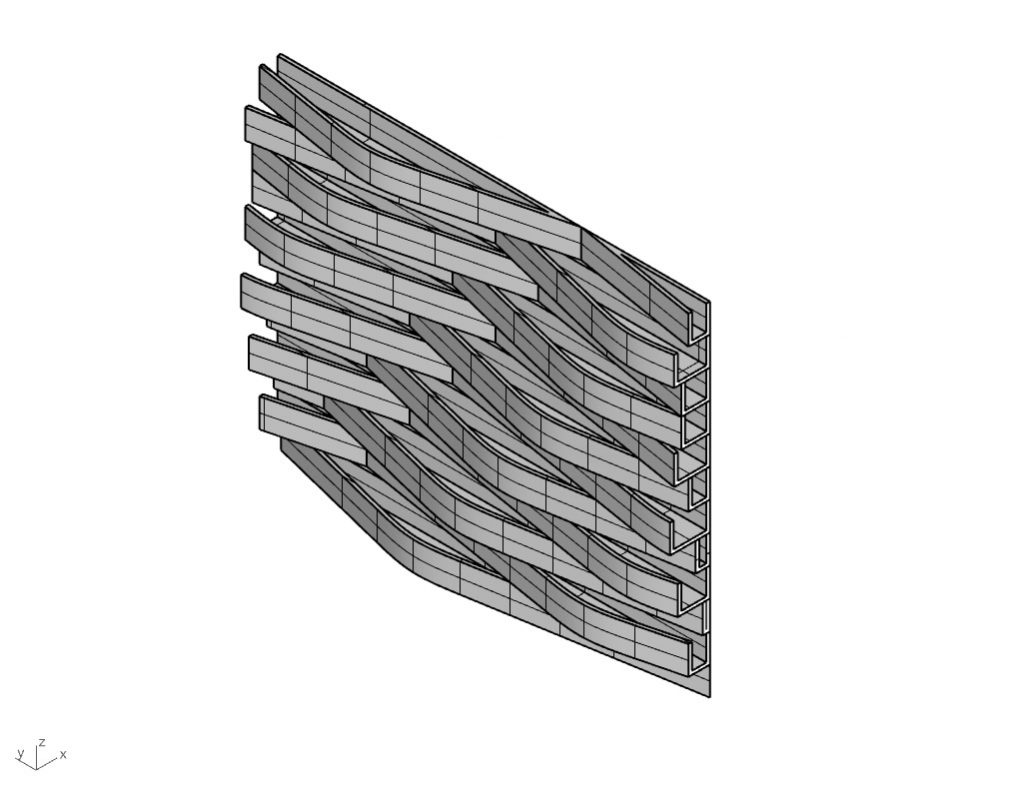

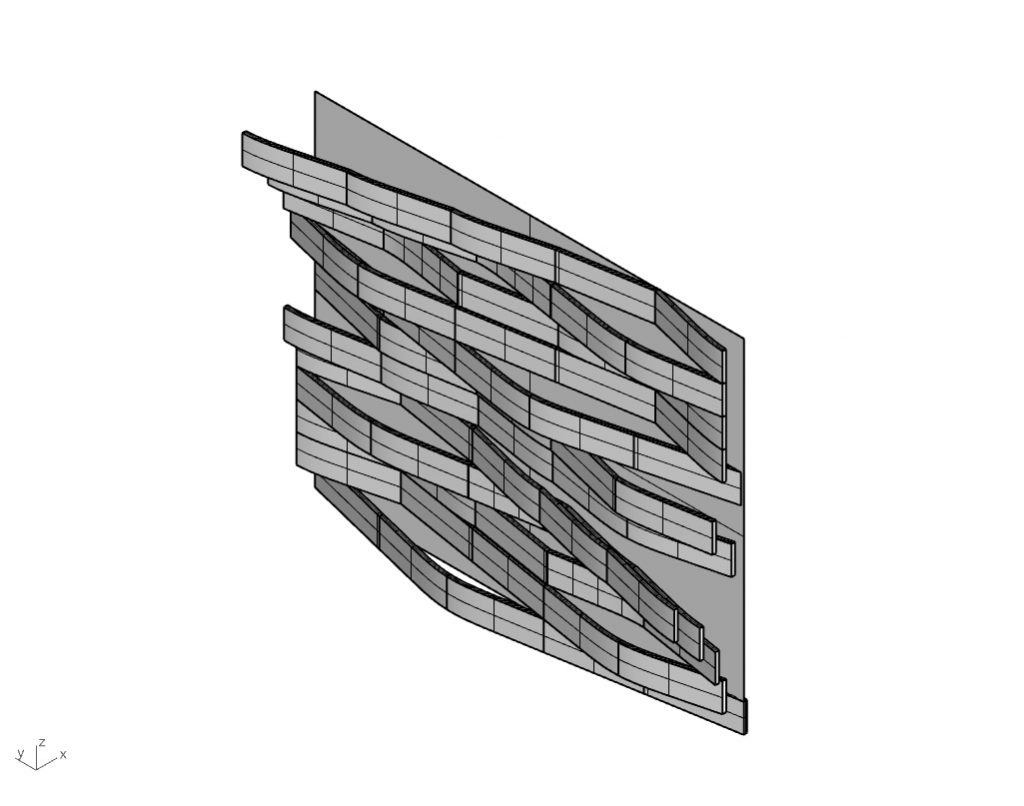

Crevice had many beneficial items that came up durning review. Firstly, the reviewers talked about how the project was successful in handling the “green wall” challenge. Crevice assured a staggered and aesthetic design that functioned well on it’s own even if plants were not growing and there was only dirt siting in the module. Later, the reviewers got into how it would be very difficult to manufacture. They brought up other, more rare techniques that could be used in the manufacturing process rather than our slip cast. Additionally, the lip used to hang the module on the aluminum bracket was a concern. It was not a module that would use the standard mechanism, and in fact needed to be much more simple. Also, our corner condition was met with a bit of unbelievability. The reviewers thought that it was much harder than it looked, and although it was a great way to approach the corner, it would require a lot of precise, on-site work. All in all, the review helped us understand how we could improve Crevice, and explored what was working well with our design and concept.

In the future of design, we have learned how important it is to be constantly working parallel to the manufacturing end of the process. Architects/designers cannot just come up with ideas and expect them to work without any issues. Of course an idea should be as pure and conceptual as you can get in the beginning phases. However, when it comes time to constructing the project, it must be very meticulously worked out with the manufacturer to assure the vision of the design is met with the greatest ability that it can be.